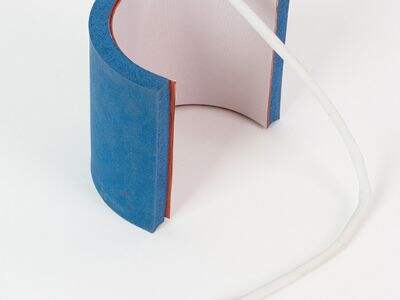

Various types of silicone rubber heaters can be used for additional needs, depending on the requirements of the project. Most of them are a spongy silicone rubber type product. A special electrically conductive material covers that silicone layer. When current runs through this conductive material, heat is produced. They can be very useful in heating up various other objects or surfaces as this heats up, hence the versatility.

The post How Silicone Rubber Heaters Work appeared first on Silicon Rubber Heater Pad.

Several parameters may influence the performance of a silicone rubber heater. For example, the thickness of the silicone layer is one such parameter. The thicker layer could better retain the heat, whereas the thinner one may be beneficial for faster heating. It is also critically dependent on the type of electrically conductive within the film. Not all materials conduct electricity in the same way, which influences the amount of heat produced. Lastly, the so-called electrical resistance of the material is also involved. It is not electricity, but it is used for electric heating. Resistance is a hindrance to electricity. Too much resistance may also limit the heat produced.

Advantages of Silicone Rubber Heaters

Silicone rubber heaters come with a lot of flexibility. They can be molded into the shape of the objects in question, whether they be round, flat, or otherwise peculiar in shape. They also allow the design of different amounts of heat generated, depending on what a given project calls for. Sometimes, a lot of heat is needed, and other times, just a little will suffice.

Silicone rubber heaters also tend to be very effective heaters when it comes to elements for heating. Since the electrical conductive material comes into direct contact with a layer of silicone rubber, most of the energy put in at the heater is transferred across with negligible loss to the object that needs warming. They find lots of applications because of their high efficiency.

Another important advantage of silicone rubber heaters is that they are durable and long-lasting. They are also designed to work over a wide range of temperatures, so they can be used in very hot and cold locations. They can also easily resist damage from chemicals and other environmental conditions without losing their heating capabilities. Their strength makes them reliable in many industries and applications.

How to Select the Right Silicone Rubber Heater

There are so many factors to consider in choosing a silicone rubber heater. For instance, consider the size and shape of an object or surface you intend to heat. A heater that is fitted perfectly will work far better. Consider also how much heat you need for your project. Not all heaters give out the same amount of heat; hence you want to choose one that gives your exact needs.

The environment in which the heater will be used is also a significant consideration. Is it going to be extremely hot or cold? Is it going to be getting chemicals or moisture? These can affect the efficiency of the heater. The quality of the heater itself matters, too. Choose a heater that is constructed using high-quality materials and employs good manufacturing practices. Ali Brother is a reliable supplier for custom-made heating solutions as they have vast experience in designing bespoke heating solutions for a wide range of diverse applications and industries.

Installation and Maintenance of Silicone Rubber Heaters

Once you are ready to put in a silicone rubber heater, the heater needs to be attached properly to the object that is being heated. Make sure there are no gaps left between the heater and the object because, again, gaps are one of the ways you lose heat. If placed correctly, the heater works even more efficiently.

The wiring is another critical part. Be certain to install and properly secure these. Be sure to follow all of the manufacturer's instructions carefully to avoid having the heater wired incorrectly. This will assist in avoiding any electrical problems which may develop while in use.

Cleaning Your Silicone Rubber HeaterCleaning your silicone rubber heater regularly is necessary to ensure that it continues to work well for many years. Dust and dirt can collect and affect its performance. Do also make sure that you do not expose the heater to any extreme chemicals or environmental factors which might degrade the heating element. This will make your heater last longer and function better.

How to Operate Your Silicone Rubber Heaters

Well, when opting for a high-quality silicone rubber heater and following the best practices as far as installation and maintenance is concerned, you can be very sure that your custom heating solution will perform at its very best for the years to come.

You are looking forward to warming up your medical device, laboratory equipment, or an industrial machine using silicone rubber heater and will look up to expertise and experience offered by Ali Brother as they have all that is expected of such an experience and professionalism for performing their task when you really need that.

EN

EN