Get faster results and safer printing with a silicone pad for your heat press

As technology improvements, companies must keep pace employing their clients' needs and trends. One of the ways for this is through innovating items that can change lives. Heat pressing is not the exception. This advanced process of needs equipment designed to care for high temperatures and pressure. A silicone pad for heat press from Ali Brother may be simply what you will have to take your printing game to the next degree. If you are going to understand the benefits, safety precautions, and also the different applications this product, continue reading.

Silicone pads are manufactured from a heat resistant item which is non-stick. This aspect is crucial in heat publishing because it prevents the ink from staying with the area of this printer. Furthermore, silicone thermal pads of Ali Brother are reusable and easy to completely clean, giving you the probability of printing large quantities stopping to wash the pads.

An additional benefit is the fact quality is improved by them of one's prints. The silicone surface is flat and smooth, ensuring even pressure circulation, that leads to a credit card uniform application. This uniformity guarantees your designs will soon be impressively bold and vibrant.

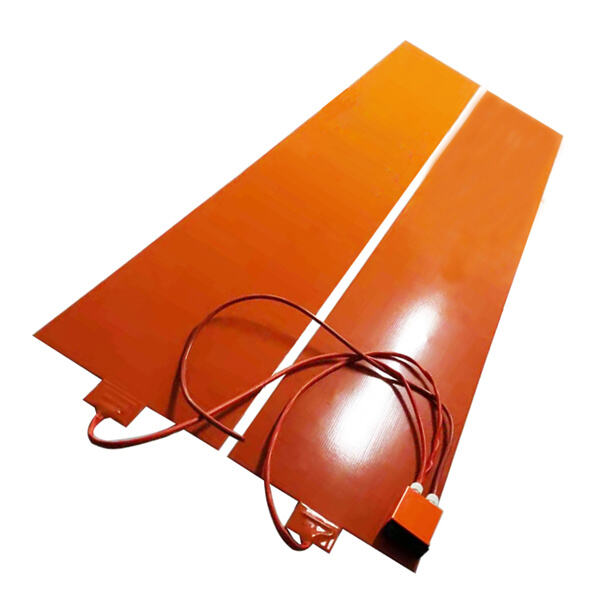

Furthermore, silicone pads are durable and affordable. These are typically made out of materials that withstand high temperatures, making them go longer than traditional pads. This durability means you cut costs on buying replacement pads frequently.

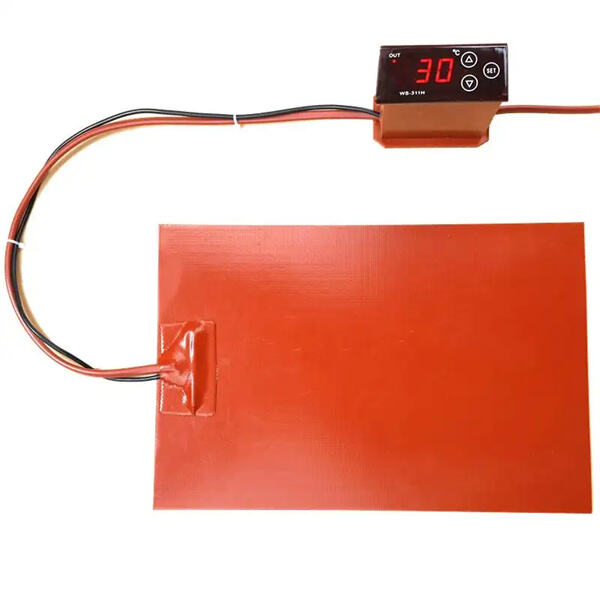

Silicone pads are an innovation to heat definite publishing. They've been made to bring about the publishing procedure easier, faster, and safer. The silicone material of a Ali Brother heating pad electricity is safe to work with and prevents accidents, such as burns or mishandling.

Security precautions are paramount in heat transfer publishing, and the utilization of silicone pads in the accepted place of traditional pads ensures that you operate under an operating protected environment. You will be enabled by this protection to pay attention to your own designs printing without worrying all about the threat of accidents.

A silicone pad is not hard to work well with you spot it beneath the fabric to be printed and then put the fabric over the top from this. The heat press rubber mat can withstand temperatures being high ensuring it does perhaps not damage the fabric throughout the printing process.

When utilizing your Ali Brother silicone pad be sure to help keep it clean in order to prevent ink buildup and longer ensure it lasts. Use a wet baby cloth wipe it down, but do not use a cleansing solvent. The solvent can damage the silicone material, reducing its efficiency.

The silicone pad for heat press has dedicated logistics partners that will be able go more than 70 countries, offering better and quicker logistics support services.

The company successfully passed ISO 9001 and IATF 16949: 2006 international quality management system certifications. Many of the products received CE ROHS and CE certifications.

The company provides a systematic after-sales assistance service and a standardized process for after-sales assistance. Their products are covered by silicone pad for heat press after-sales assistance.

Specialized in R and D production and sales of various types silicone heaters, 3D printer heating bed oil drum heaters, polyimide heaters, silicon heating cables etc. Our products are widely used in medical, food heating, electric appliances, automobile and aviation sectors. This figure can be customized processing meet your specifications.