Keep your machines cool with Thermal Pad Silicone.

Within the current world electronic machines are becoming to be more complex and effective. They could do so significantly more that they generate more heat than they might before, but this does mean. This might be where Ali Brother thermal pad silicone comes in, as it assists to keep your machines cool. The advantages shall be discussed by us about Thermal Pad Silicone, its innovation, safety, simple tips to use, service, quality, and application.

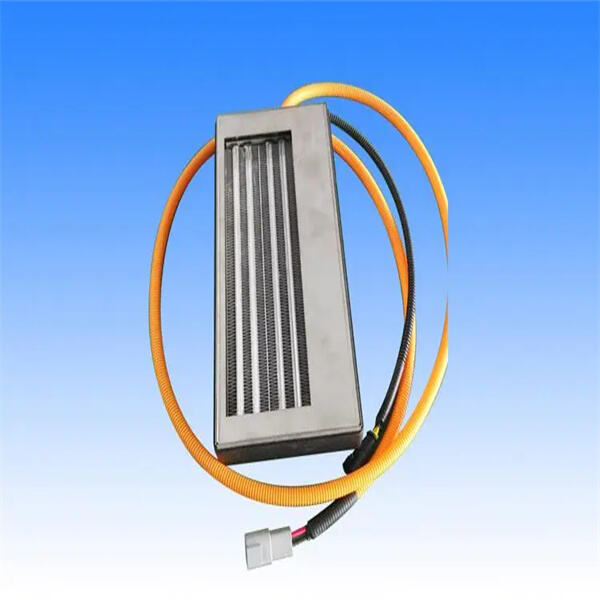

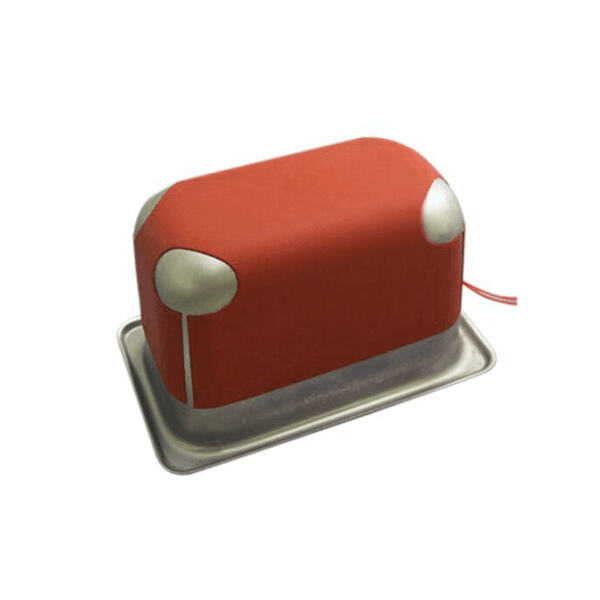

Thermal Pad Silicone has numerous advantages that make it a popular choice engineers and manufacturers. First, Ali Brother silicone rubber heating pad is an excellent thermal conductor ensures heat is moved out of the source. Second, it is flexible and can fill gaps between the machine and the heat sink. This can help to boost the area and enhances heat dissipation. Thirdly, it is possible to use and calls for no curing time. Lastly, it is available and affordable in a variety of sizes and thicknesses.

Thermal Pad Silicone has undergone some noticeable changes it had been first introduced. Ali Brother silicone heating pad with thermostat manufacturers have taken significant steps improve its thermal conductivity, freedom, and durability. These innovations allow Thermal Pad Silicone to do even a lot better than before, giving engineers and manufacturers more choices to keep their machines cool.

Thermal Pad Silicone is a safe product use it is non-toxic and non-carcinogenic. Ali Brother thermal conductive silicone pad is also resistant to high temperatures rendering it well suited for machines that generate heat. It is eco-friendly, and some manufacturers produce it using methods may be sustainable.

Using Thermal Pad Silicone is a simple operation. First, clean the surface associated with the heat sink and the machine where the Thermal Pad Silicone would be used. Cut the Thermal Pad Silicone to your depth dimensions appropriate required. Then, apply the Ali Brother silicone heating pad onto the temperature sink or the machine, with respect to the supposed use. Lastly, connect the heat sink towards the machine, making sure there was great contact the 2 surfaces.

The company has a standardized after-sales support service system, standardized after-sales support process, company's products have an up-to-date thermal pad silicone support after sales duration.

We are specialized in R and D and production of various silicone heaters. This includes 3D printers heat oil drums, polyimide heating cables, silicone heating cables, etc. Our products are extensively used in medical, food heating electrical appliance and automobile industries.

Most products come with a CE and ROHS certifications.

Our thermal pad silicone partner dedicated that can go more than 70 countries, offering safer and faster logistics support services.